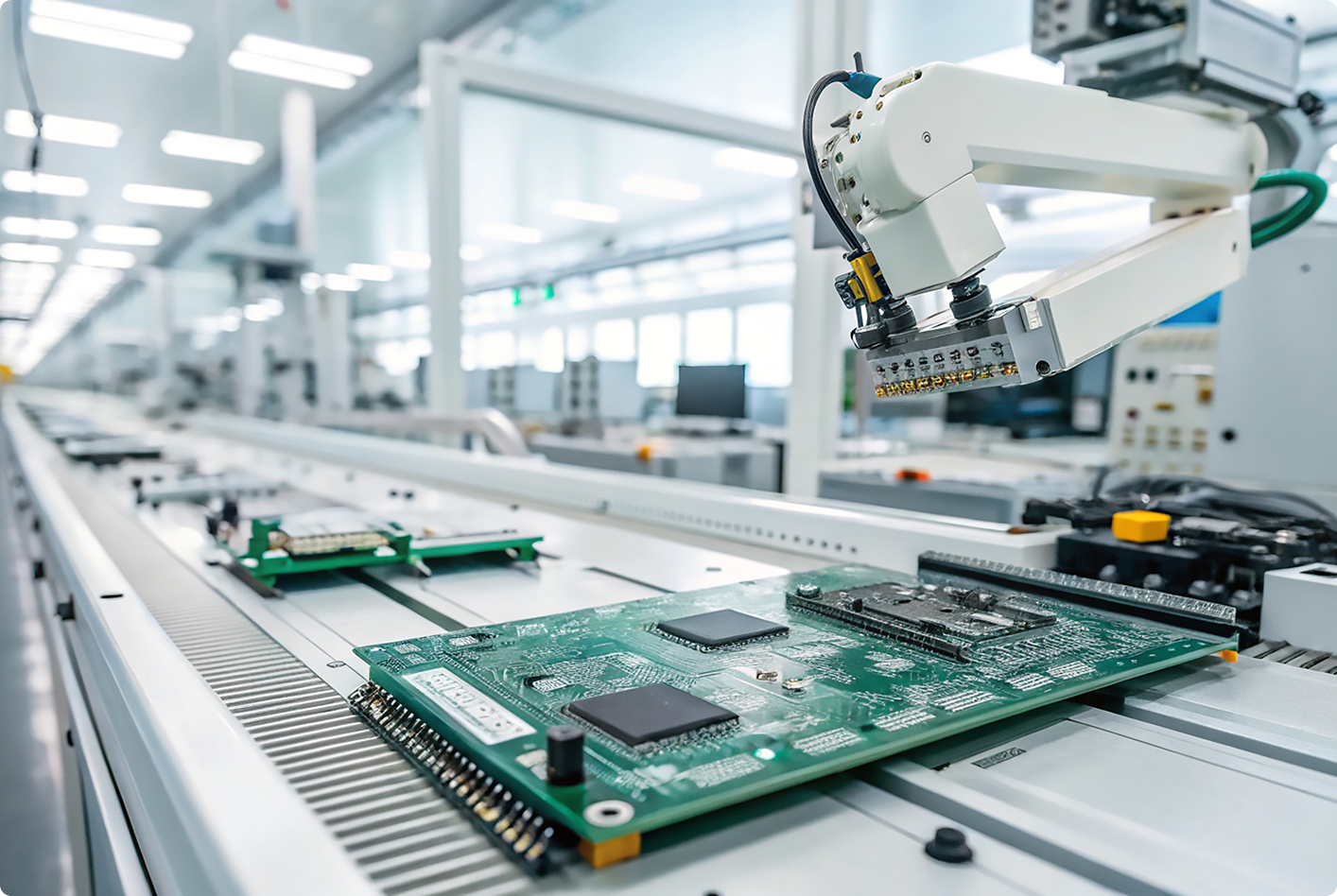

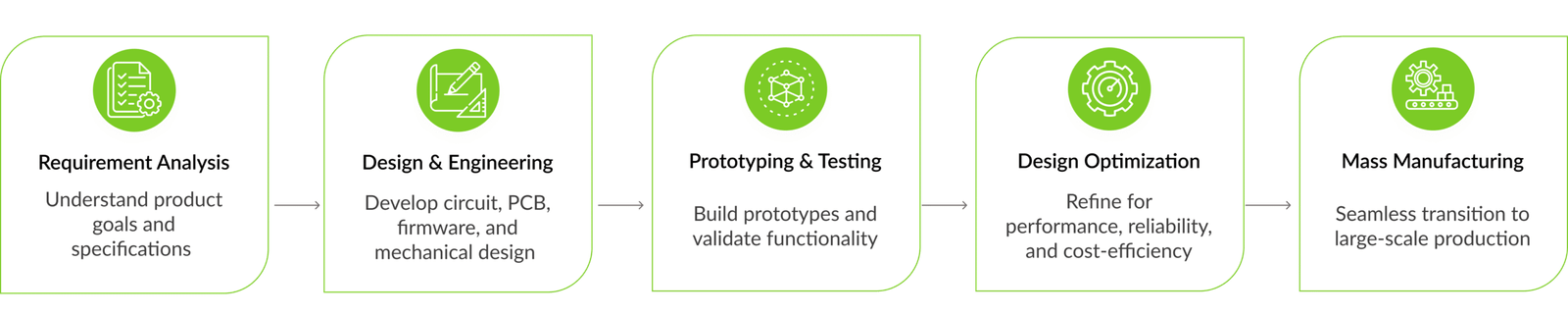

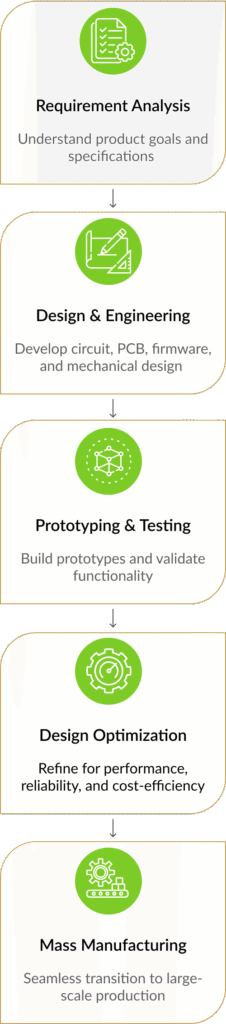

From electronic design to assembly and testing.

100+ years of global design and manufacturing experience

Fast turnaround for testing and validation.

ISO- and RoHS-compliant processes with automated testing.

Tailored designs for performance, cost, and scalability.

We power diverse industries — from consumer electronics to automotive, healthcare, and defense — through innovation, precision, and reliability, delivering world-class design and manufacturing excellence that helps global brands build smarter, more efficient, and future-ready electronic systems.

Real-time monitoring and digital traceability for every product.

Inline AOI, SPI, and reflow inspection ensuring zero-defect builds.

High-mix, low-volume, or mass production with rapid changeover.

Direct coordination with inhouse ODM design teams.

Secured component sourcing with vendor-managed inventory.

Solar power, waste recycling, and green operational standards.

PCBA Units / Year

Set Top Boxes / Year

Indoor Display Units / Year

From concept design to delivery, everything managed under one roof for seamless execution.

MES-enabled traceability and lifecycle tracking ensuring quality and efficiency.

Global team with expertise in AIDC, IoT, Automotive, and Defence sectors.

Backed by ₹1000+ Cr turnover and strong capital resources from Emprada Group.

6-acre smart facility with a 7.5-acre expansion-ready land bank.

Financially strong, technologically agile, and globally recognized partner.

EmpradaTEK offers complete electronics manufacturing services in India, including PCB design, PCB assembly, component sourcing, prototyping, and final product assembly. As a trusted EMS provider in India, we handle both turnkey and consignment projects with precision and reliability.

Quality is our top priority. Every product goes through multiple inspection stages, including automated optical inspection (AOI) and functional testing. Our ISO certified EMS company follows strict quality standards and RoHS compliance to ensure consistent, high-quality output.

Yes. EmpradaTEK specializes in low-volume and prototype manufacturing, helping clients test and refine their products before mass production. Our flexible setup allows quick turnaround times for R&D and pilot projects.

Absolutely. Our manufacturing facility is ISO and RoHS certified, ensuring compliance with international standards. This guarantees safe, environmentally responsible, and reliable contract electronics manufacturing services.

Yes. EmpradaTEK supports global shipping and logistics for all completed electronic assemblies and devices. We manage documentation, customs clearance, and secure packaging for safe worldwide delivery.

We provide complete PCB assembly services in Tirupati, including SMT, through-hole, and mixed-technology assembly. Our team ensures high accuracy, fast turnaround, and cost-effective production for all project sizes.

Yes. We offer reliable component sourcing and supply chain management to ensure timely availability of genuine components. Our partnerships with verified vendors help reduce lead times and costs.

EmpradaTEK delivers electronics manufacturing services in India for multiple industries, including consumer electronics, automotive, medical devices, IoT, and industrial automation. Our custom solutions fit both startups and established companies.