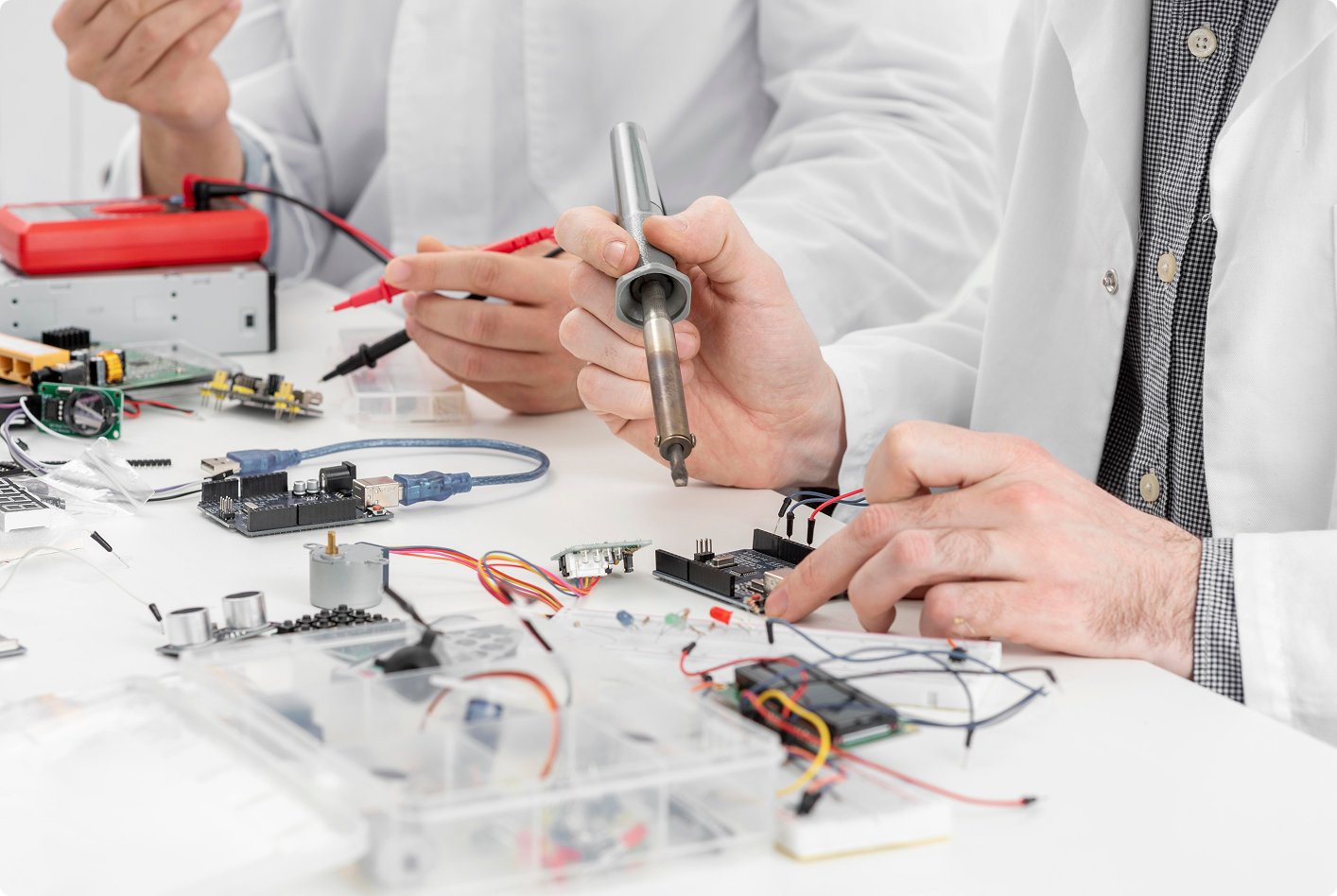

From electronic design to assembly and testing.

100+ years of global design and manufacturing experience

Fast turnaround for testing and validation.

ISO- and RoHS-compliant processes with automated testing.

Tailored designs for performance, cost, and scalability.

We power diverse industries — from consumer electronics to automotive, healthcare, and defense — through innovation, precision, and reliability, delivering world-class design and manufacturing excellence that helps global brands build smarter, more efficient, and future-ready electronic systems.

Multi-layer PCB design with high-speed signal routing and optimization.

Thermal, ergonomic, and compliance-focused product design solutions.

Integrated software development for IoT and smart connectivity devices.

Simulation, reliability, and lifecycle testing ensuring performance assurance.

Optimized for scalability, cost efficiency, and production yield.

Unified collaboration across R&D, manufacturing, and quality engineering.

PCBA Units / Year

Set Top Boxes / Year

Indoor Display Units / Year

From concept design to delivery, everything managed under one roof for seamless execution.

MES-enabled traceability and lifecycle tracking ensuring quality and efficiency.

Global team with expertise in AIDC, IoT, Automotive, and Defence sectors.

Backed by ₹1000+ Cr turnover and strong capital resources from Emprada Group.

6-acre smart facility with a 7.5-acre expansion-ready land bank.

Financially strong, technologically agile, and globally recognized partner.

ODM (Original Design Manufacturer) refers to a company that designs, develops, and manufactures electronic products based on its own designs, which clients can rebrand and sell. It covers the full process — from concept to production.

Timelines vary depending on complexity. Generally, concept to prototype takes 6–12 weeks, while full production can take 3–6 months. Custom designs or certifications may extend the schedule.

Yes, our product design and development services allow full or partial customization — from appearance and features to firmware and packaging — ensuring the product reflects your brand’s identity.

We follow strict IP protection policies and sign NDA (Non-Disclosure Agreements) before starting any project. All design files, schematics, and source codes remain confidential and can be transferred to the client upon request.

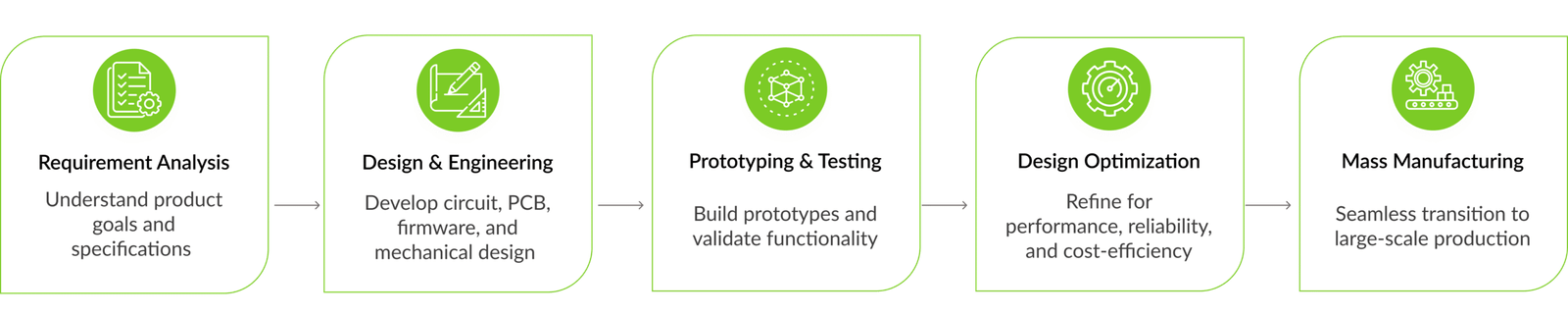

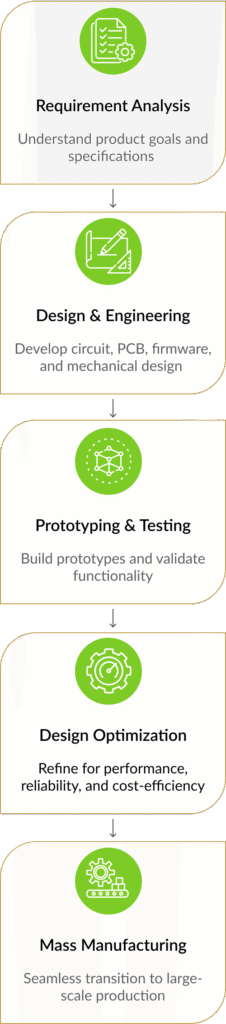

Our turnkey product design process includes:

Concept design & feasibility study

Circuit design and PCB layout

Electronic prototyping and testing

Firmware/software development

Design validation

Mass manufacturing and quality control

Yes, we provide rapid electronic prototyping and manufacturing support to validate designs, test functionality, and ensure quality before full-scale production begins.

We work across industries like consumer electronics, IoT devices, automotive electronics, healthcare, industrial automation, and smart home products.

Yes. As a turnkey product design company, we manage product certifications such as CE, RoHS, FCC, BIS, and others to ensure your product meets global standards and market requirements.